Energy – The central granulator for large-volume parts and high throughput

PRODUCTS

Energy

Die Zentralschneidmühle für großvolumige Teile und große Durchsätze

The Wanner Energy-Series

The central granulator for large-volume parts and high througput

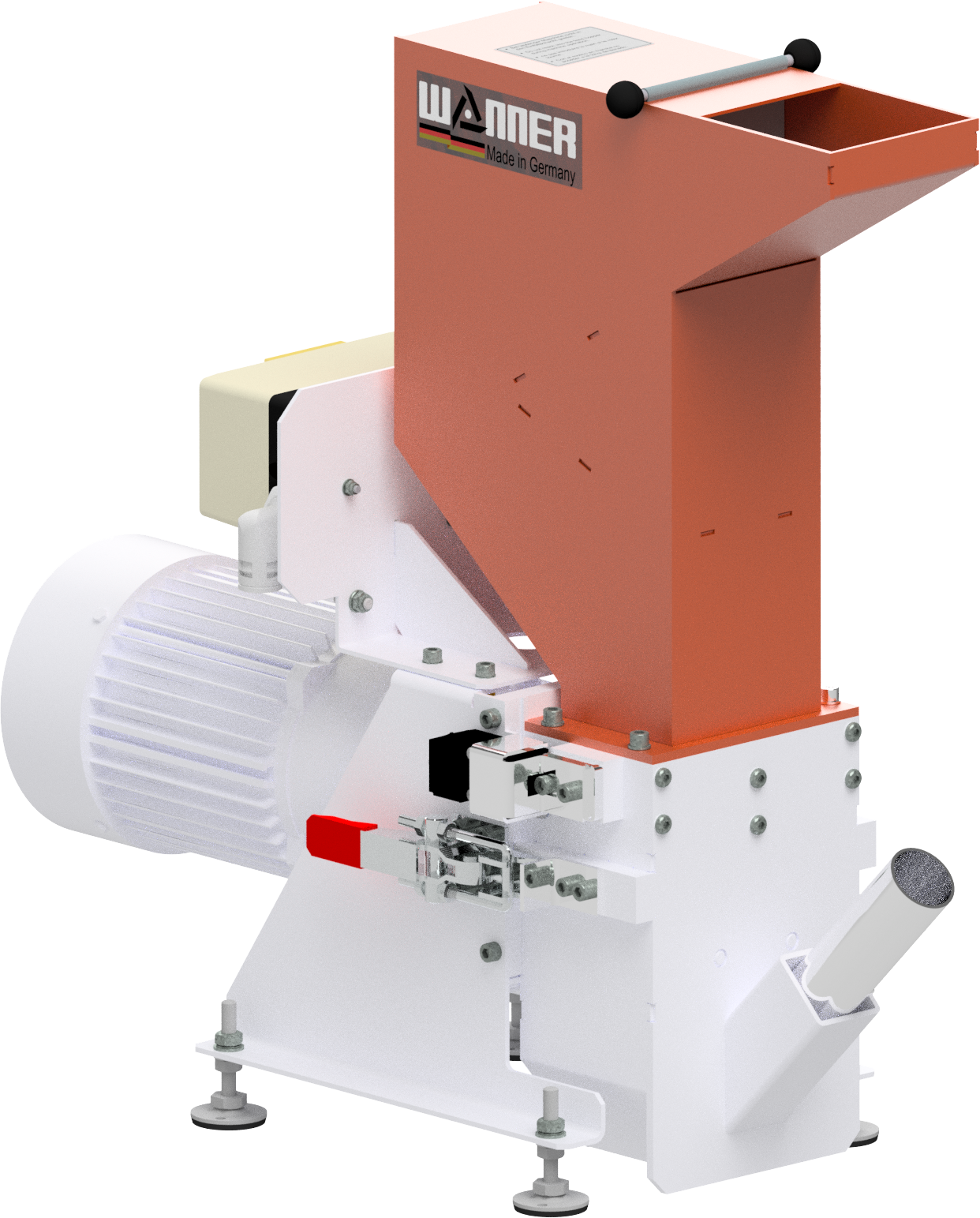

The E-series granulators are perfectly suited to function as powerful central granulators as well as granulating systems built in-line grinding to process tops and tails as well as rejects generated during the manufacture of large blow-moulded parts.

A total of five cutting chamber sizes as well as various cutting chamber configurations and different feed hopper types allows to adapt the machines specifically to meet the customer’s needs and to the type of material feeding.

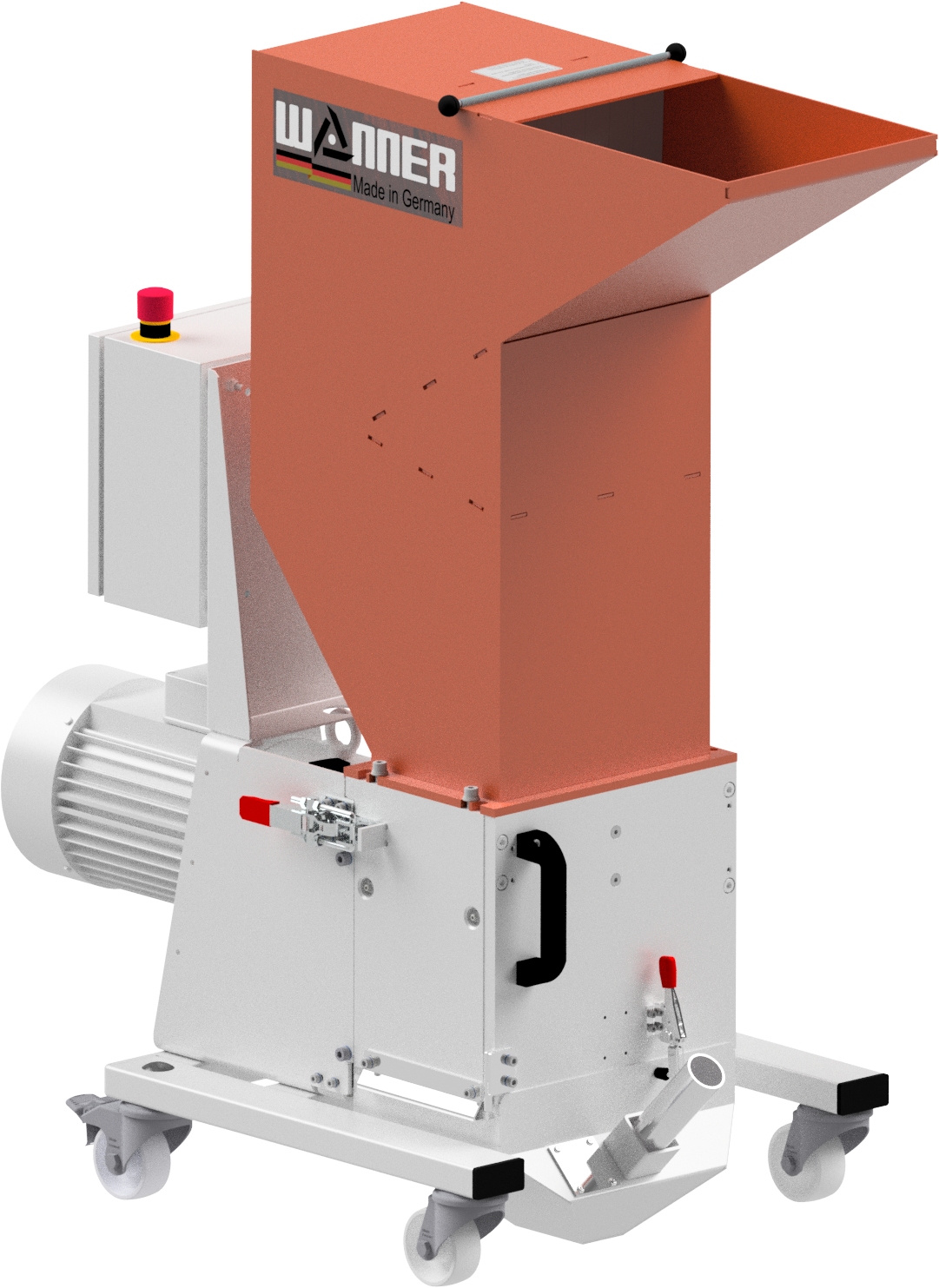

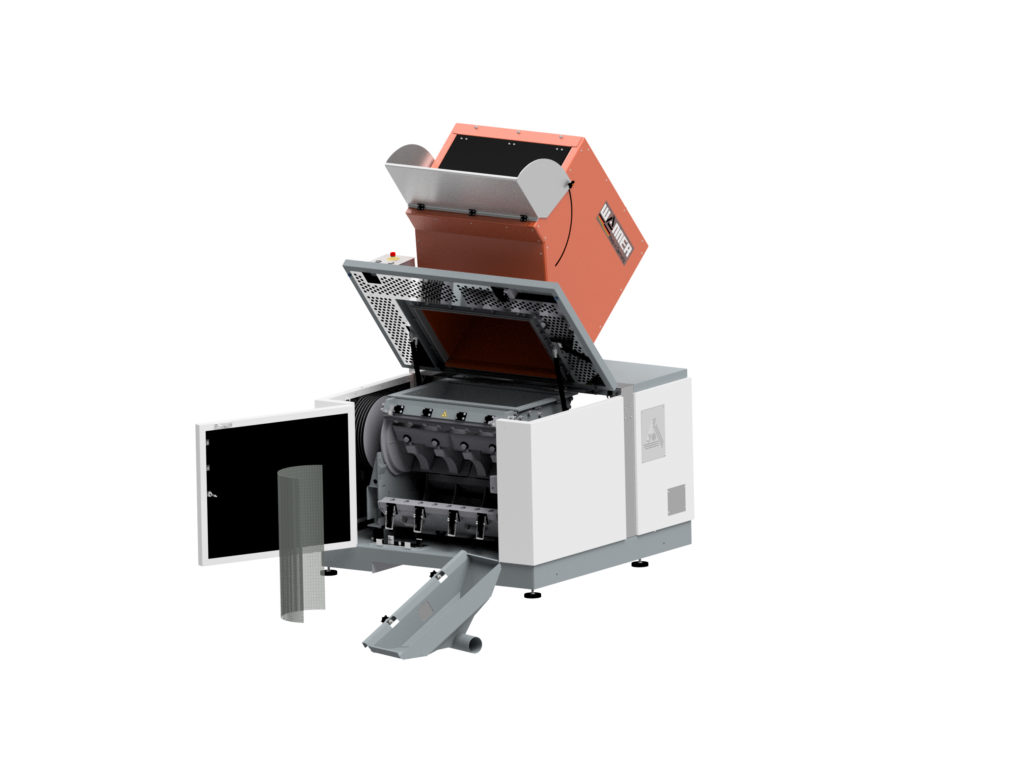

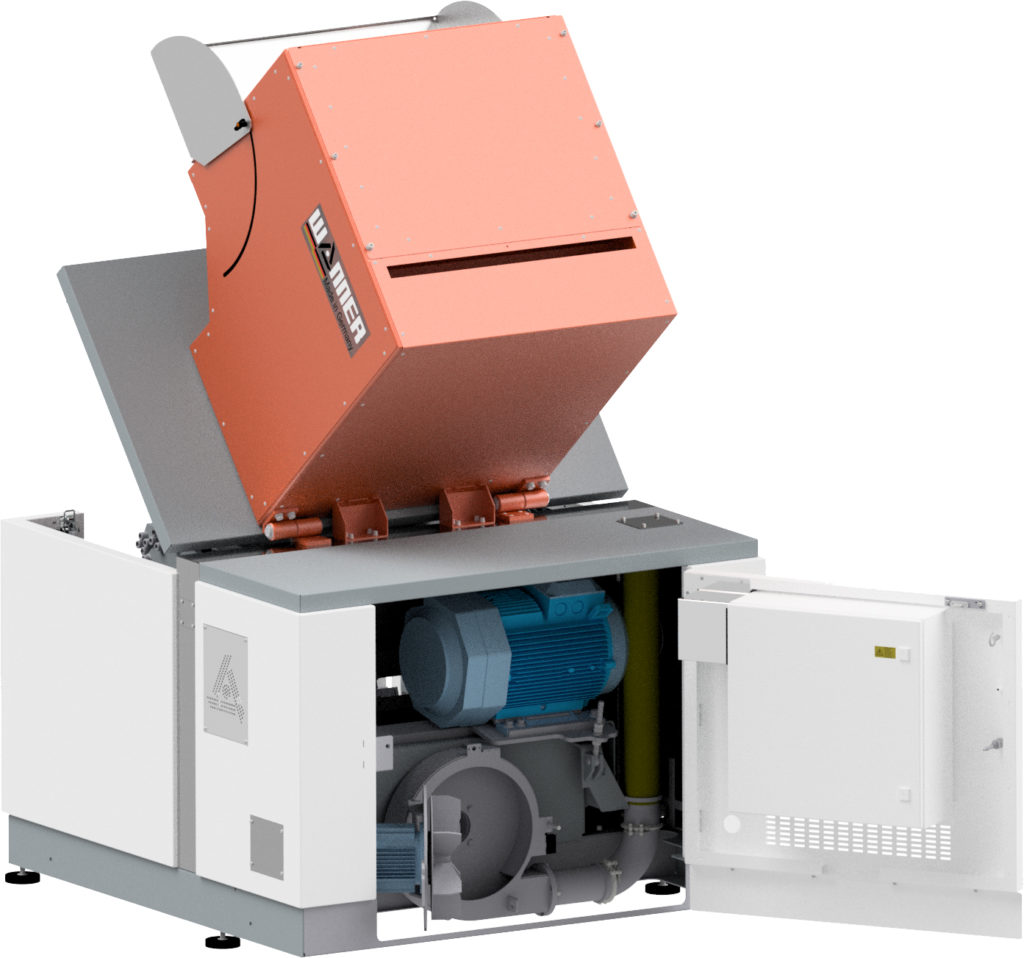

Granulators in the E Series are equipped with an integrated sound enclosure into which the optionally available material transport blower can be integrated. Furthermore, vibration elements decouple the grinding chamber from the booth, thus dampening the vibrations.

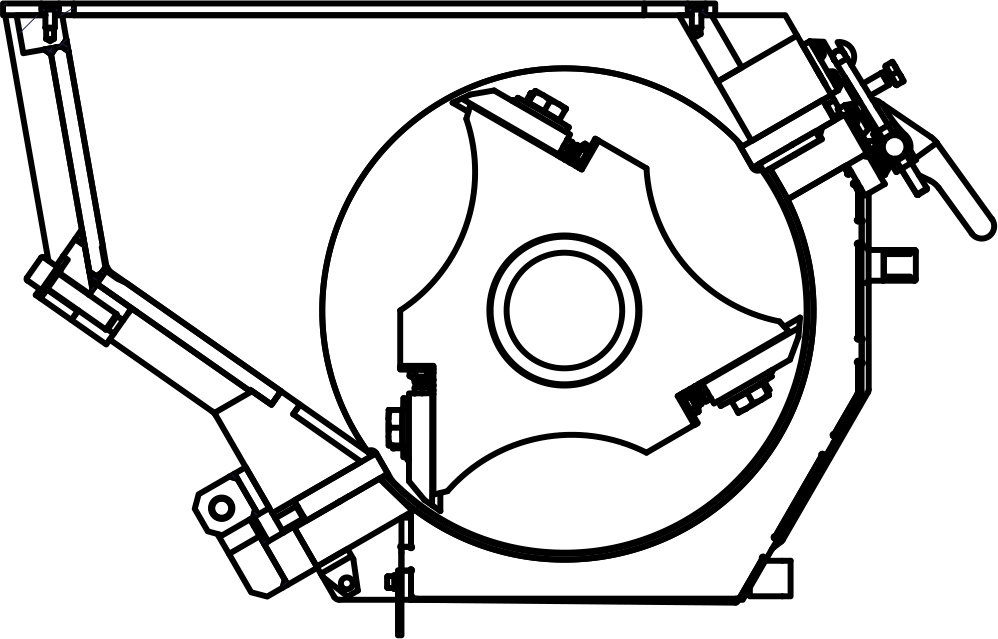

The cutting chamber is designed as a robustly sized structure held together by welding and screws, the rotor shaft runs on oversized bearings.

The granulator’s cutting chamber and blower can be accessed quickly and easily without any tools through the wide-opening access doors. Cleaning the granulator is easy.

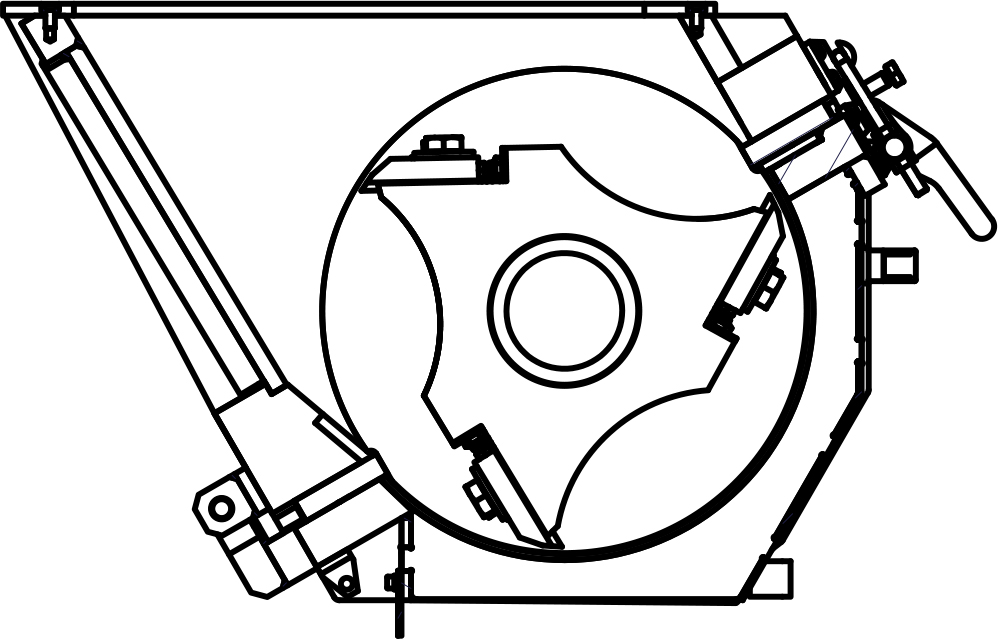

Three-edged rotor with standard grinding chamber – the universal solution for parts and sprues

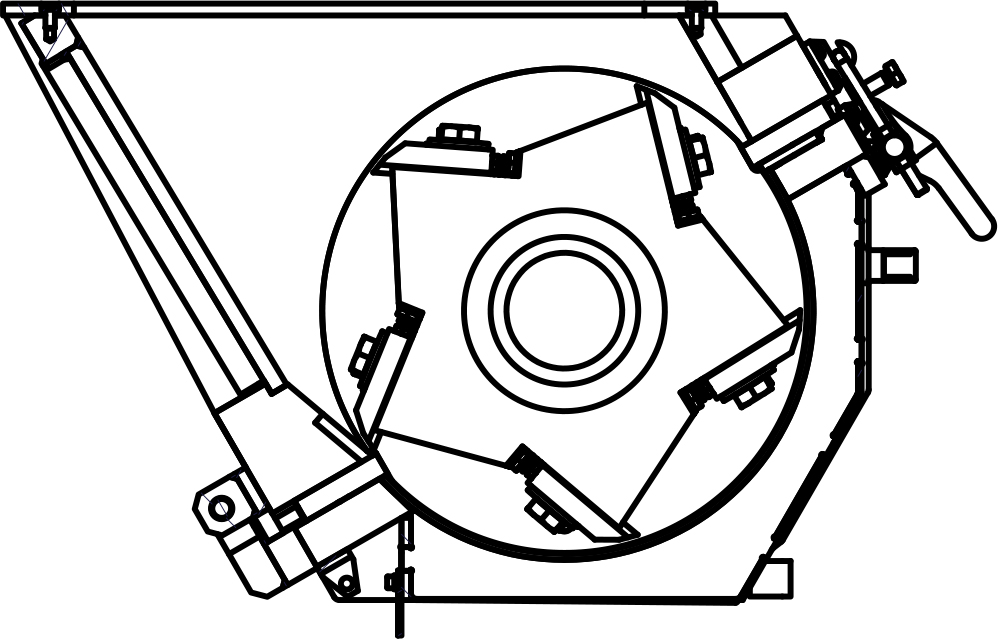

Five-edged rotor with standard grinding chamber – for larger throughputs

Three-edged rotor with super-tangential cutting chamber – for processing especially voluminous parts

- Sound enclosure integrated as standard into machines of the series

- High regrind material quality thanks to Chevron-cutting design

- Aggressive rotor design for reliable pull-in action of very large parts, optional super-tangential grinding chamber available

- Five-edged rotor available for extra high throughputs

- Optional blower can be integrated into the sound enclosure

- Cutting chamber decoupled from the machine frame and sound insulating booth for effective insulation of the structure-borne noise

- Extensive accessories available, including various blowers, cyclones, rotative wheel gates, dust removal systems, conveyor belts, and much more

Everything integrated and easily accessible

Granulators from our Energy Series are available with an optional blower integrate into the standard sound enclosure that is easily accessible through a large back door. Incorporating the blower into the sound enclosure of the granulator sustainably dampens the noise generated. In order to save space, the blower is installed at the back in the sound enclosure and accessible through a wide opening door. The robustly designed blower itself is also hinged for easy opening. Depending on customer requirements, the blower as well as the pipe bends can be provided in a wear-protected design, so that even fibreglass-reinforced materials can be reliably processed.

| E 30.50 | E 35.40 | E 35.60 | E 45.50 | E 45.80 | |

| Mahlraumöffnung | 300 x 500 mm | 350 x 400 mm | 350 x 600 mm | 450 x 500 mm | 450 x 800 mm |

| Rotordurchmesser | 250 mm | 300 mm | 300 mm | 400 mm | 400 mm |

| Rotormesser | 2 x 3 | 2 x 3 oder 2 x 5 | 2 x 3 oder 2 x 5 | 2 x 3 oder 2 x 5 | 2 x 3 oder 2 x 5 |

| Statormesser | 2 | 2 | 2 | 2 optional 3 | 2 |

| Schnittgeometrie | V-Schnitt | V-Schnitt | V-Schnitt | V-Schnitt | V-Schnitt |

| Motorleistung | 7,5 kW – 11 kW | 11 kW – 18,5 kW | 18,5 kW | 18 kW – 30 kW | 22 kW – 30 kW |

| Rotordrehzahl | 630 U/min | 500 U/min | 500 U/min | 450 U/min | 450 U/min |

| Gewicht | 1000 kg | 1300 kg | 1450 kg | 1850 kg | 2200 kg |

| Durchsatz* | 150-200 kg/h | 200-250 kg/h | 300-500 kg/h | 300-500 kg/h | 400-800 kg/h |

* Der Durchsatz gilt für Standardmaterialien wie z. B. PA, ABS, PS etc. bei Verwendung des Standardsiebs und stellt einen Richtwert dar. Er ist abhängig von Siebgröße, Material, und Größe der Angüsse und kann je nach Anwendung unter Umständen deutlich von den hier genannten Werten abweichen.

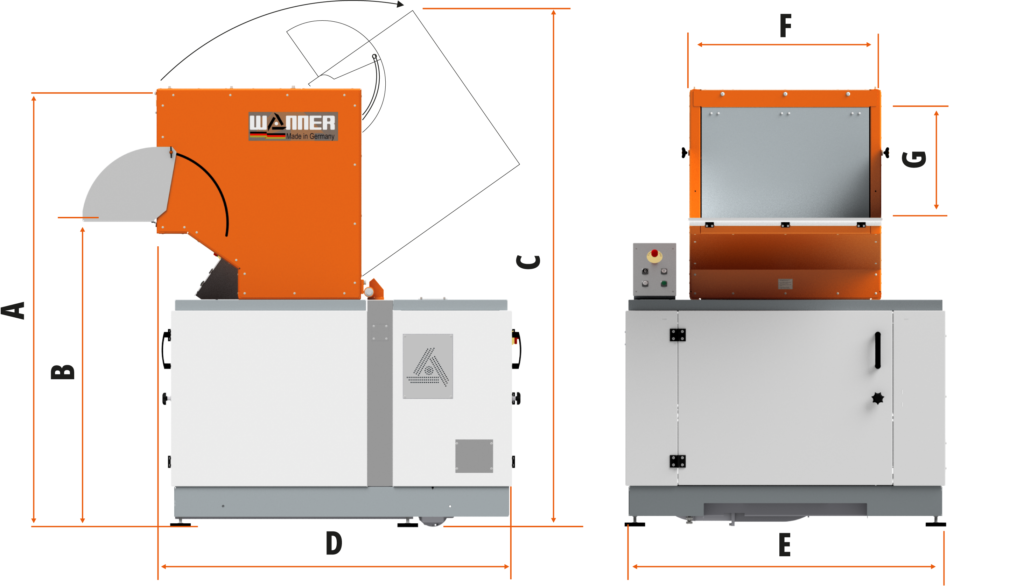

Die E-Serie: Maßskizze

| E 35.50 | E 35.40 | E 35.60 | E 45.50 | E 45.80 | |

| A | 1915 | 1960 | 1960 | 2100 | 2100 |

| B | 1405 | 1450 | 1450 | 1505 | 1505 |

| C | 2250 | 2320 | 2320 | 2520 | 2520 |

| D | 1625 | 1760 | 1760 | 1745 | 1745 |

| E | 1000 | 960 | 1260 | 1100 | 1540 |

| F | 505 | 430 | 630 | 510 | 810 |

| G | 430 | 430 | 430 | 545 | 545 |

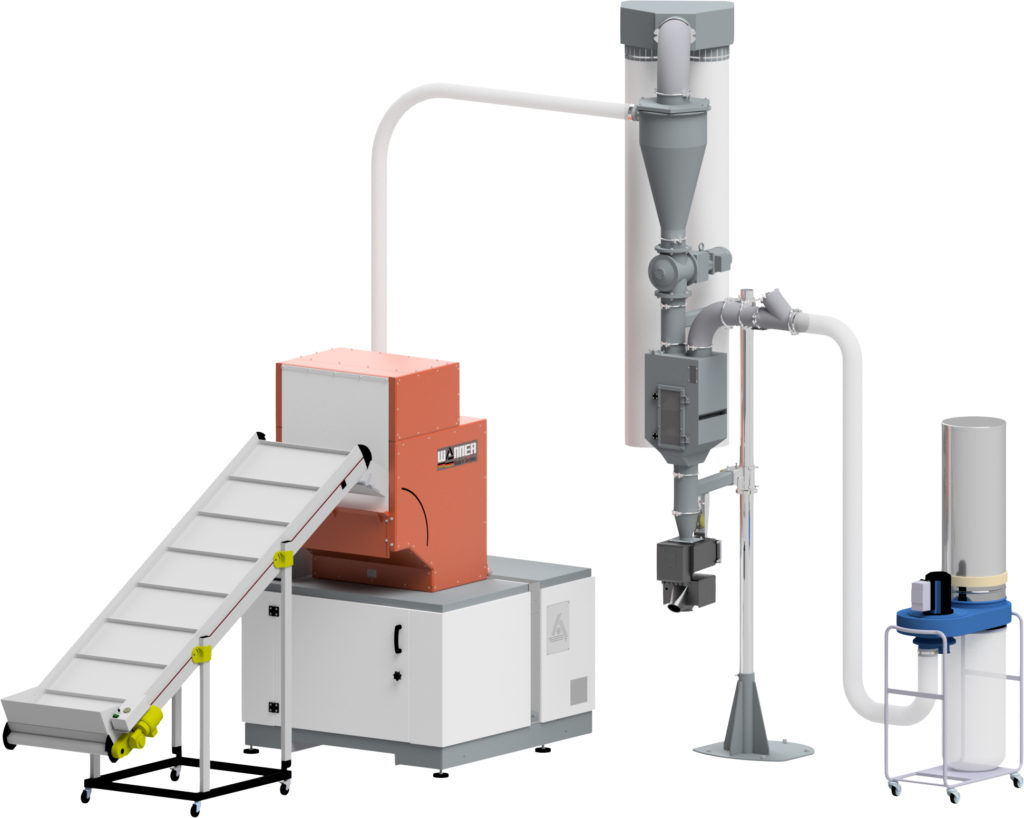

Von der Schneidmühle bis zum Mahlzentrum:

Falls ein zentralisiertes Mahlen benötigt wird, lassen sich mit unseren Scheidmühlen aus der Energy-Serie sehr einfach zentrale Mahlstationen für Durchsätze bis zu 500 kg/h generieren.

Neben der zu Ihren Anforderungen passenden Schneidmühle liefern wir auch die gesamte Peripherie, angefangen vom Fördergebläse mit der passenden Verrohrung, dem Zyklonabscheider mit Gestell, und falls gewünscht auch Zellenradschleuse, Metallseparator und Förderband mit oder ohne Metallsuchspule. Für sehr lärmsensitive Bereiche besteht zudem die Möglichkeit, die gesamte Schneidmühle zusätzlich zu kapseln, so dass solche Zerkleinerungsanlagen auch zentral und produktionsnah in einer Halle aufgebaut werden können. Gebläse und Zyklone sind dabei hinsichtlich der für die Förderung notwendigen Luftmengen soweit aufeinander abgestimmt, dass Granulat und Luft sauber getrennt werden. Die beiden groß dimensionierten Filtersäcke sorgen dafür, dass die Umgebung weitgehend unbelastet bleibt. Falls Sie hier besondere Anforderungen haben, sprechen Sie uns einfach an.

E 35.60 Sonderschacht mit seitlicher Zuführung

Für spezielle Anwendungen können wir unsere Maschinen genau auf die Bedürfnisse unserer Kunden anpassen. So fertigen wir Sonderschächte mit zusätzlicher seitlicher Zuführung, falls z.B. auch längere Profilabschnitte zerkleinert werden müssen.

Für spezielle Anwendungen können wir unsere Maschinen genau auf die Bedürfnisse unserer Kunden anpassen. So fertigen wir Sonderschächte mit zusätzlicher seitlicher Zuführung, falls z.B. auch längere Profilabschnitte zerkleinert werden müssen.

Je nach Kundenanforderung passen wir unsere Schächte darauf an, wie das zu zerkleinernde Material der Mühle zugeführt werden soll. Durch die Verwendung unterschiedlicher Rotoren, die z.B. 3-schneidig oder 5-schneidig ausgeführt sind, oder die Verwendung von Mahlräumen mit unterschiedlicher Einzugsgeometrie können wir unsere Schneidmühlen sehr gut auf Ihre Anforderungen hinsichtlich Teilegröße und Durchsatz anpassen. Weitere Optionen wie ein zusätzlicher Verschleißschutz im Mahlraum oder beim Gebläse, sowie eine Vielzahl an Steuerungsoptionen ermöglichen uns, auch schwierigste Anforderungen zu erfüllen. Egal ob Blasteile, Spritzgussteile oder Extrusionsprofile – wir haben sicher eine Lösung für Ihr Zerkleinerungsproblem.

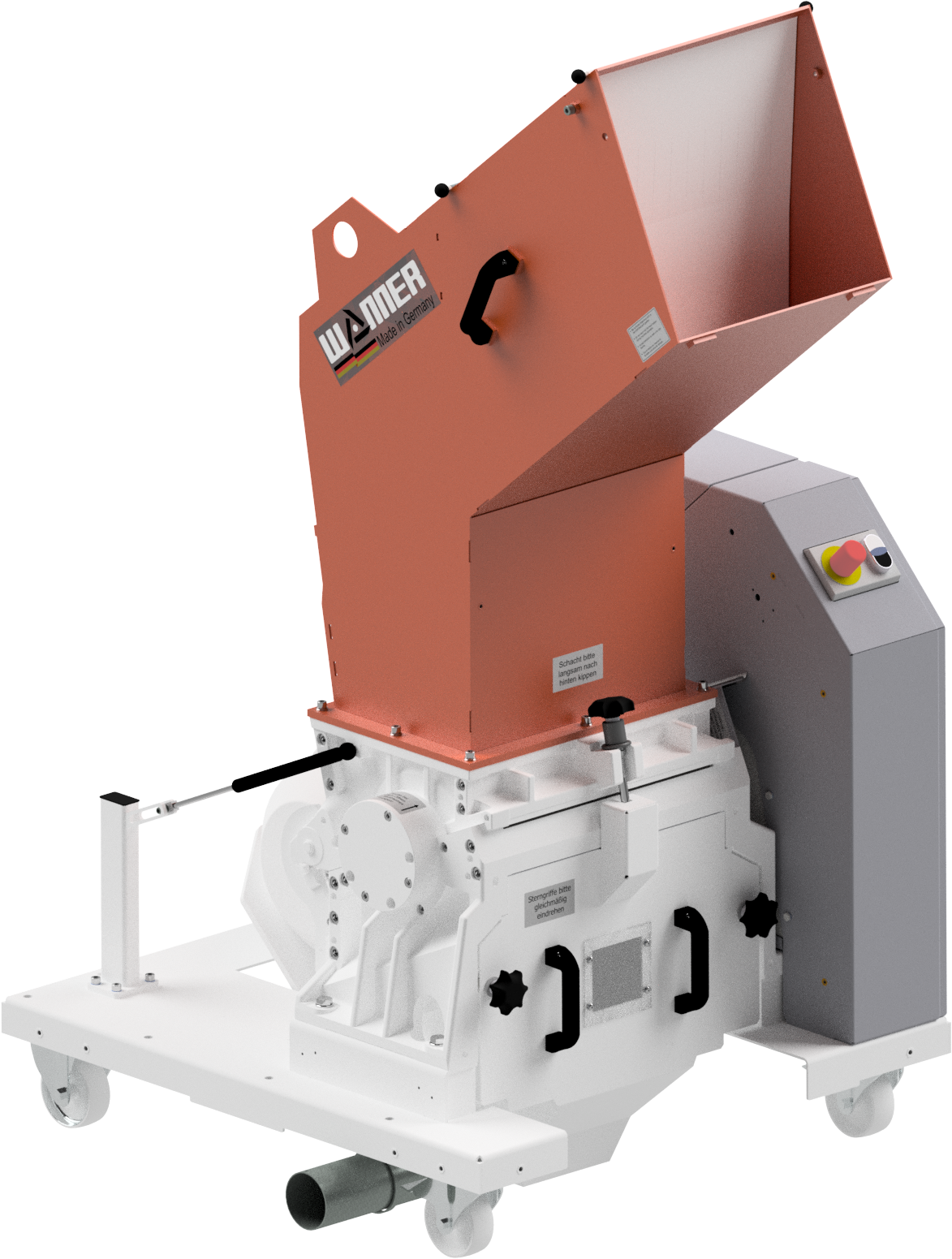

Die Energy-Serie – so einfach zugänglich

Die Schneidmühlen unserer Energy-Serie sind standardmäßig mit einer integrierten Schallschutzkabine ausgerüstet. Durch eine sich weit öffnende Tür und den…

…federunterstützt weit aufklappenden Zuführschacht ist der Mahlraum für Reinigungs- und Servicearbeiten schnell und gut zugänglich. Der Siebbügel lässt sich ohne Werkzeug öffnen und das Sieb kann dann ebenfalls einfach entnommen werden.

Bei einigen unserer Kunden in Schwaben heißen unsere Schneidmühlen wegen der einfachen Zugänglichkeit und der Bedienerfreundlichkeit deshalb einfach die „Schnellputzmühlen“. Ein Name den wir als Kompliment und Verpflichtung auffassen.

Die Wanner Energy Baureihe

Dauer: 03:21 min

Messerwechsel bei der Wanner Energy Baureihe

Dauer: 07:02 min

The Energy-Series

Anfrage

DOWNLOADS