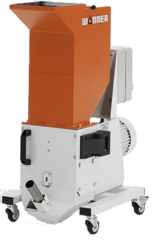

TG-Extruder – The compact repelletise system

PRODUCTS

TG-Extruder

The compact repelletise system

The TG-Series

The compact repelletise system

The new ThermoGran20 allows you to transform problematic ground stock as well as small parts / sprues directly into high-quality granulate. The TG20 produces granulates which are comparable in quality and flow characteristics with corresponding new material. Granulate produced by the TG20 can be re-used or added to your production process with absolute confidence. The TG20 plasticizes and granulates all types of polymers safely and reliably and is the right solution in all situations where granulate produced by purely mechanical crushing cannot be processed correctly. The system comprises a compact, slow running extruder with a large infeed area and special worm geometry with a large auxiliary worm, allowing granulate which does not flow well or powder as well as whole sprues and small parts to be fed in with ease. A water quench integrated in the system with downstream strand granulator allows the material strands to be cut precisely so that a highly homogeneous granulate is produced which flows well and can be easily dosed. The TG20 is equipped with a reliable control system capable of handling sophisticated processing parameters for safe processing of difficult materials. The automated system uses sensors to adapt the speed of the extruder to the infeed behavior of the material and to match the extraction speed of the granulator with production conditions to ensure process stability even with varying material characteristics. The TG20 is also suited for compounding applications such as colour dying or for the production of micro granulates.

- Ideal to process inhomogeneous, non-uniform regrind e.g. containing larger parts, dust, slivers etc

- Suitable for a wide range of Polymers (e.g. TPE, EVA, PP, PE, ABS, PS, PA, PC, POM etc.)

- Also suitable for compounding special formulations or colors especially for TPE and Polyolefins – also economical for small quantities

- Production of micro pellets possible

- Plasticises the material without damaging it due to low speed Operation

- Large infeed section with additional feed auger allows processing of critical granulate with large content of powder or large pieces

- Easy to operate control

- Compact unit including water bath and pelletizer

- Economical due to short payback time

| TG20/2 | TG20/3 | |

|---|---|---|

| Motor power extruder: | 4 kW | 4 kW |

| Motor power granulator: | 0,37 kW | 0,37 kW |

| No. of heating zones | 2 (barrel) | 3 (barrel) |

| Heating power | 3 kW | 3 kW |

| Speed extruder: | 0 – 34 rpm | 0 – 34 rpm |

| Output: | Max. ca. 20kg | Max. ca. 20kg |

| Infeed area: | Auger + auxiliary auger | Auger + auxillory auger |

| Power supply: | 400 V / 50 Hz | 400 V / 50 Hz |

| Weight: | ca. 600 kg | ca.650 kg |

| Control: | PLC | PLC |

Videos

TG-Extruder: Start up

Duration: 02:53 min

Professional recycling of plastic caps to granulate

TG-Extruder: Operating

Duration: 04:04 min

The TG-Extruder

Application

DOWNLOADS